Recognize the telltale signs that your coal-burning system needs help: smoke backing up into your living space, difficulty getting fires started, weak flames that smolder rather than burn vigorously, or excessive creosote buildup in your chimney. These frustrating problems often stem from inadequate draft—the natural upward flow of air that removes combustion byproducts and feeds oxygen to your fire.

Install a chimney draft fan to mechanically boost airflow when natural draft falls short. These powerful devices mount at the top of your chimney and actively pull smoke and gases upward, overcoming common obstacles like short chimney height, cold weather inversions, nearby tall structures blocking wind patterns, or airtight modern homes that limit makeup air. The right fan transforms a smoky, inefficient heating system into a clean-burning, reliable heat source that keeps your family comfortable throughout winter.

Assess your specific situation before purchasing equipment. Measure your chimney’s height, diameter, and flue tile condition. Document when draft problems occur—constantly, only during startup, or in specific weather conditions. Calculate your coal stove’s BTU output to match fan capacity appropriately. Understanding these factors prevents costly mistakes and ensures you select a draft inducer that solves your exact problem rather than creating new complications.

Prioritize safety and efficiency together. A properly sized chimney draft fan not only eliminates smoke spillage but also improves combustion efficiency, reducing coal consumption and minimizing your environmental footprint while maximizing the cozy warmth that makes coal heating an attractive, sustainable lifestyle choice for modern homeowners seeking alternatives to conventional energy sources.

Understanding Coal Heating Draft Problems

Why Coal Creates Unique Venting Challenges

Coal burning presents distinctive venting challenges that set it apart from other heating fuels, and understanding these differences is essential for maintaining a safe, efficient heating system in your home.

Unlike wood or gas, coal is an incredibly dense fuel that burns with remarkable intensity but at surprisingly lower flame temperatures. This might seem counterintuitive, but it’s one of the key coal combustion characteristics that affects your chimney’s performance. The dense nature of coal means you’re packing significantly more fuel into your firebox, which generates substantial heat output but also produces greater volumes of combustion gases that need to be vented efficiently.

The lower flame temperature creates a particular challenge for draft performance. When flames burn cooler, the exhaust gases don’t rise as readily through your chimney. In traditional fireplace design, hot gases naturally create the updraft that pulls fresh air into the fire and pushes smoke out. With coal’s cooler combustion, this natural draft effect weakens, making it harder for your chimney to do its job effectively.

Perhaps most importantly, coal requires continuous, steady burning to maintain efficiency. Unlike wood fires that you might let die down between loadings, coal stoves and furnaces work best with consistent fuel beds that burn around the clock during heating season. This continuous operation demands reliable, uninterrupted draft to prevent dangerous smoke spillage into your living space.

These factors combine to create situations where natural draft alone often falls short, making chimney draft fans not just helpful additions but frequently necessary components for safe, effective coal heating in your home.

Signs Your Coal System Has Draft Issues

Recognizing draft problems early can save you from inefficient heating and potential safety hazards. If you’re noticing smoke puffing back into your room when you open the stove door or light a fire, that’s your first red flag. Proper draft should pull smoke up and away, not into your living space where it affects both air quality and your family’s comfort.

You might also struggle to get your coal fire started or keep it burning consistently. Coal needs steady airflow to ignite properly, and weak draft creates frustratingly slow starts. Once burning, poor draft leads to excessive clinker buildup—those hard, fused ash deposits that block airflow and reduce your stove’s efficiency.

Temperature fluctuations throughout your home often signal inconsistent combustion caused by draft issues. Your fire may burn too hot one moment and smolder the next, making it nearly impossible to maintain that cozy, steady warmth you’re looking for.

Watch for heavy creosote accumulation in your chimney too. While coal produces less creosote than wood, inadequate draft causes incomplete combustion, leading to dangerous buildup that increases fire risk. If you’re cleaning your chimney more frequently than expected or noticing thick, tar-like deposits, your draft system likely needs attention. These signs shouldn’t be ignored—they’re your heating system asking for help to perform safely and efficiently.

What a Chimney Draft Fan Actually Does

The Science Behind Assisted Draft

Think of your chimney like a natural engine that runs on temperature differences. Natural draft happens when warm air inside your chimney rises and cooler outside air rushes in to replace it, creating an upward pull that carries smoke away. This works beautifully when conditions are just right, but reality often has other plans.

Enter negative pressure situations, which are the nemesis of good draft. When your home is too airtight, when wind patterns work against you, or when outdoor temperatures rival your indoor warmth, that natural upward flow weakens or even reverses. This is where mechanical draft assistance becomes your ally.

A chimney draft fan creates consistent, reliable airflow regardless of weather conditions or atmospheric pressure. By mechanically pulling air up and out of your chimney, these fans overcome the physical limitations that plague natural draft systems. The fan essentially takes control of the venting process, ensuring combustion gases exit properly every single time.

Why does this matter for coal heating efficiency? Coal needs steady, adequate oxygen supply to burn cleanly and completely. Poor draft means incomplete combustion, wasted fuel, creosote buildup, and potentially dangerous smoke spillage into your living space. A properly functioning draft fan transforms unreliable heating into a consistent, efficient, and safer home comfort solution.

Where Draft Fans Fit in Your Venting System

Understanding where your draft fan sits in your venting system dramatically affects how well it handles coal heating challenges. Each position offers distinct advantages worth considering for your home.

Chimney top fans mount directly on your chimney crown, creating powerful suction that pulls smoke and combustion gases upward. This position works exceptionally well for coal applications because it addresses the entire draft column at once, overcoming the stubborn resistance that heavy coal smoke creates. These fans handle the corrosive byproducts of coal burning effectively since they’re positioned away from the most intense heat and chemical exposure.

Inline fans install within your flue pipe, offering a more compact solution that’s easier to access for maintenance. They work best when your draft problems stem from specific sections of your venting path rather than overall height issues.

Flue pipe fans attach to horizontal or angled sections, providing targeted boost where gravity can’t help. While useful for wood burning, they face greater stress from coal’s aggressive emissions and require more frequent attention.

For coal heating specifically, chimney top installations typically deliver the most reliable, long-lasting performance while keeping your home’s warmth and comfort consistent throughout the heating season.

When Your Coal System Actually Needs a Draft Fan

Common Scenarios That Demand Mechanical Draft

Understanding when you need a mechanical draft solution can save you from ongoing frustration and help you enjoy your fireplace or heating appliance safely. Let’s explore the situations where a chimney draft fan becomes more than just helpful—it becomes essential for proper operation.

If you have a short chimney, typically less than 15 feet from the firebox to the top, you’re working against basic physics. Chimneys rely on height to create natural draft, and shorter systems simply don’t generate enough upward pull to evacuate smoke efficiently. This is particularly common in single-story homes or installations with low rooflines.

Exterior chimneys in cold climates face their own challenges. When your chimney runs up the outside wall of your home, the flue stays cold, making it harder for warm air to rise. This is especially problematic during startup when you’re trying to establish draft, and the temperature differential just isn’t working in your favor.

Modern homes, with their excellent insulation and tight construction, create what’s called negative pressure. Your home is so well-sealed that there’s not enough makeup air for the chimney to draw from, resulting in sluggish draft or backdrafting. This same issue affects homes with powerful kitchen exhaust fans that compete for air.

Oversized flue pipes present another common problem. If previous owners installed a liner or flue that’s too large for your current heating appliance, the space doesn’t heat up efficiently, weakening your natural draft considerably.

Finally, geographical factors matter tremendously. Homes located in valleys, surrounded by tall trees, or in consistently windy locations often battle unpredictable draft conditions that make mechanical assistance the most reliable solution for consistent, safe operation.

Problems a Draft Fan Won’t Fix

Before investing in a chimney draft fan, it’s important to understand that some underlying issues need attention first. Think of it this way: a fan can’t fix a fundamentally compromised system any more than a powerful exhaust fan can fix a cracked window.

Cracked or deteriorated chimney liners are deal-breakers. If your liner has structural damage, a draft fan will simply pull combustion gases into the spaces between your liner and chimney walls, creating dangerous carbon monoxide risks in your living space. You’ll need professional liner repair or replacement before any fan installation makes sense.

Major blockages like bird nests, debris accumulation, or even collapsed masonry require removal first. A fan can’t create airflow through a blocked passage, and attempting to do so may push smoke and gases back into your home.

Significantly undersized chimneys present another challenge. If your chimney is too narrow for your heating appliance’s output, even the most powerful fan becomes a band-aid solution. You might consider switching to dual fuel options that better match your existing chimney dimensions, or investing in proper chimney modifications.

The good news? A qualified chimney professional can assess these structural issues during an inspection, helping you determine whether a draft fan is the right solution or if you need to address foundational problems first.

Choosing the Right Draft Fan for Coal Heating

Types of Draft Fans for Coal Systems

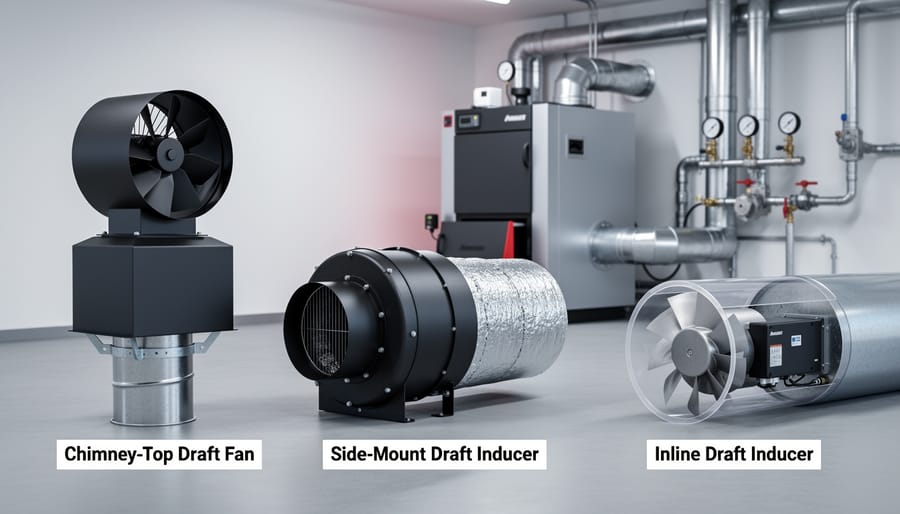

When you’re heating with coal, choosing the right draft fan can make the difference between a cozy, efficient fire and a smoky, frustrating experience. Let’s explore your three main options and help you find the perfect match for your setup.

Chimney top fans mount directly on your chimney cap and are the powerhouses of draft enhancement. They actively pull combustion gases up and out, making them ideal for coal stoves experiencing significant draft issues or homes with short chimneys that struggle to generate natural draft. These fans work wonderfully for coal heating because they handle the dense smoke and particulates that coal produces. However, they require electrical installation and regular maintenance to keep them running smoothly through those cold winter months when you need them most.

Inline draft inducers sit within your chimney system, closer to the stove itself. These compact units boost draft right where it matters most and are excellent for moderate draft problems. They’re often easier to install than chimney top fans and provide reliable performance for most coal heating situations. Think of them as the middle-ground solution that balances power with practicality.

Barometric dampers offer a passive approach to draft management. Rather than adding draft, they regulate it by automatically opening or closing to maintain consistent pressure. These work best when you already have adequate natural draft but need to prevent overdrafting, which can waste fuel and reduce efficiency. For coal systems with variable weather conditions affecting draft, barometric dampers provide steady, eco-friendly operation without electricity.

Your choice depends on your specific challenges. Severe draft issues call for chimney top fans, moderate problems suit inline inducers, and overdrafting situations benefit from barometric dampers.

Sizing Considerations for Coal Combustion

Selecting the right chimney draft fan capacity for your coal-burning fireplace isn’t guesswork—it’s about matching your system’s specific needs to ensure safe, efficient operation. Think of it as finding the perfect partner for your heating setup, one that works harmoniously with your existing infrastructure.

Start by considering your chimney height. Taller chimneys naturally create more draft, so they may need less mechanical assistance. For every 10 feet of chimney height, you’ll gain some natural draft power. Next, measure your flue diameter—a 6-inch flue moves less air than an 8-inch, affecting the fan size you’ll need.

Your coal appliance’s BTU output is crucial. A typical residential coal burning systems might produce 40,000 to 80,000 BTUs. Generally, you’ll need a fan capable of moving 15-20 cubic feet per minute per 10,000 BTUs of output. So a 60,000 BTU stove would require roughly 90-120 CFM capacity.

Don’t forget elevation factors—homes above 3,000 feet experience thinner air, reducing natural draft by about 3-4% per 1,000 feet. This means mountain dwellers typically need more powerful fans than those at sea level. When in doubt, consult with a certified chimney professional who can calculate the precise requirements for your unique setup.

Features Worth Having (And Paying For)

When choosing a chimney draft fan, certain features transform a basic solution into a long-term investment. Variable speed controls top the list, allowing you to fine-tune airflow based on outdoor temperature, fuel type, and burn intensity. This flexibility means you’re not stuck with one setting that’s either too weak on calm days or unnecessarily powerful during optimal conditions.

For coal-burning systems specifically, high-temperature ratings matter tremendously. Coal produces more heat than wood, so your fan needs components rated for sustained exposure to extreme temperatures. Look for models rated at least 500°F, with stainless steel construction that won’t corrode from acidic coal combustion byproducts.

Weather protection features extend your fan’s lifespan considerably. Quality units include rain caps, sealed motors, and weatherproof housings that withstand harsh winters without constant maintenance. This eco-friendly approach means fewer replacements and less waste over time.

Finally, consider automatic versus manual operation. Automatic fans with temperature sensors activate only when needed, saving electricity and reducing wear. Manual controls offer simplicity and complete control for those who prefer hands-on management of their heating system. Your choice depends on whether you value convenience or direct oversight of your home’s warmth.

Installation and Safety Essentials

Professional Installation vs. DIY Considerations

Installing a chimney draft fan isn’t the most complicated home improvement project, but it does require careful consideration of your comfort level and local regulations. Many mechanically inclined homeowners can successfully install draft fans, especially plug-in models that mount on the chimney top. However, this project involves working on your roof and dealing with electrical connections in a high-moisture, high-temperature environment.

If you’re comfortable with ladder work, basic electrical wiring, and following detailed instructions, a DIY installation might save you several hundred dollars. You’ll need to properly seal the fan to prevent water infiltration and ensure adequate electrical protection. The key challenge isn’t just mounting the fan, but doing it correctly to maintain your chimney’s weatherproofing and structural integrity.

That said, professional installation makes sense if you’re uncomfortable working at heights, uncertain about electrical codes, or dealing with complex chimney configurations. Building codes typically require permits for electrical work and structural modifications to chimneys. A licensed professional understands these requirements and can ensure your installation meets all safety standards while maintaining your homeowner’s insurance coverage. They’ll also spot potential issues with your chimney that could affect performance or safety, giving you peace of mind along with proper function.

Safety Protocols for Coal System Ventilation

When you’re using a chimney draft fan with coal heating, safety becomes your number one priority. Coal burning naturally produces carbon monoxide, an odorless, invisible gas that can be deadly if not properly vented. Your draft fan plays a crucial role in ensuring these combustion gases exit your home safely rather than spilling into your living space.

Start by installing a carbon monoxide detector near your coal stove or furnace—this isn’t optional, it’s essential. Even with a properly functioning draft fan, you need this backup safety measure to alert you if something goes wrong.

Measuring your draft regularly helps you maintain the sweet spot for safe, efficient coal burning. You can purchase an inexpensive draft gauge to monitor the pressure in your chimney. For most coal systems, you’re looking for a draft reading between 0.04 and 0.06 inches of water column. Too little draft means incomplete combustion and potential carbon monoxide buildup; too much creates its own problems.

Here’s something many coal burners overlook: maintaining adequate secondary combustion air. Your coal fire needs oxygen not just at the fuel bed, but above it to complete the burning process. If your draft fan pulls too aggressively without sufficient air intake, you’ll create negative pressure that can draw combustion gases back into your home.

Over-drafting is another concern that affects both safety and efficiency. When your fan pulls too hard, you’re literally sucking unburned coal particles and heat straight up the chimney, wasting fuel and money. This also creates excessive creosote buildup, increasing fire risk. Adjust your fan speed to match your coal system’s needs, creating just enough draft for clean combustion without wasteful over-venting.

Living With Your Draft Fan: Maintenance and Efficiency

Seasonal Maintenance Tasks

Keeping your chimney draft fan in top condition doesn’t require much effort, but staying on top of seasonal maintenance ensures it performs reliably when you need it most. Think of it as giving your fan a little TLC before the heating season kicks into high gear.

Before lighting your first fire each fall, inspect the fan housing and blades for dust buildup or debris that might have accumulated during the off-season. A quick wipe-down with a damp cloth keeps airflow efficient and prevents unnecessary strain on the motor. While you’re at it, check the motor mounting bolts to ensure everything remains secure.

Most modern draft fans feature sealed bearings that don’t require lubrication, but if you have an older model, consult your manufacturer’s guidelines about applying a few drops of lightweight machine oil to the motor bearings annually. This simple step can extend the motor’s lifespan significantly.

For belt-driven models, examine the belt for signs of wear, cracking, or fraying. A worn belt can slip or break unexpectedly, leaving you without proper ventilation during the coldest months. Replacing a belt is straightforward and inexpensive compared to dealing with smoke spillage issues.

Finally, test your fan’s operation before the heating season begins. Listen for unusual noises, vibrations, or changes in performance that might indicate developing problems. Addressing small issues early prevents bigger headaches later and keeps your home warm, safe, and comfortable all winter long.

Optimizing Performance for Fuel Economy

Getting the most from your chimney draft fan isn’t just about turning it on and forgetting it. Think of your fan as a dance partner with your coal stove—when they’re in sync, you’ll enjoy better fuel economy, cleaner burns, and a cozier home.

Start by running your fan at lower speeds during milder weather. You’ll use less electricity while still maintaining proper draft, and your coal will burn more slowly and completely, stretching your fuel supply. On particularly cold days when you need more heat, gradually increase the speed rather than jumping to maximum right away.

Watch your coal bed closely. If you’re seeing lots of unburned pieces or excessive ash, your draft might be too strong, literally pulling heat up the chimney before your coal can release its full energy. Conversely, if combustion seems sluggish with visible smoke, bump up the speed slightly.

Modern variable-speed fans often include thermostats or timers, letting you automatically adjust draft based on actual heating needs. This smart approach reduces coal waste while keeping your home comfortable and minimizing your environmental footprint. The goal is finding that sweet spot where your coal burns completely and efficiently, giving you maximum warmth from every piece.

Choosing the right chimney draft fan truly transforms your coal heating experience from a source of constant worry into the reliable, cozy warmth you deserve. When your venting system works properly, you’re not just improving comfort—you’re protecting your family’s safety, reducing wasted fuel, and creating the dependable home environment that makes cold evenings truly special. The efficiency gains alone often offset the investment within a couple of heating seasons, while the peace of mind is simply priceless.

Take a moment to honestly assess your current setup. Are you dealing with smoke spillage, uneven burning, or rooms that never quite reach the warmth you want? These aren’t just minor inconveniences—they’re signs your system needs attention. The good news is that with proper draft management, your coal heating can deliver consistent, efficient warmth while keeping harmful gases safely outside where they belong.

Creating a truly comfortable home means more than just generating heat—it’s about doing so safely and sustainably. With the right draft fan and proper maintenance, you’re investing in years of dependable warmth, lower fuel costs, and the genuine satisfaction of knowing your heating system works exactly as it should, every single time.